Q3C — Tables and List

Guidance for Industry

U.S. Department of Health and Human Services

Food and Drug Administration

Center for Drug Evaluation and Research (CDER)

Center for Biologics Evaluation and Research (CBER)

[June 2017]

ICH

Revision 3

Q3C — Tables and List

Guidance for Industry

Additional copies are available from:

Office of Communications,

Division of Drug Information

Center for Drug Evaluation and Research

Food and Drug Administration

10001 New Hampshire Ave., Hillandale Bldg., 4

th

Floor

Silver Spring, MD 20993-0002

Phone: 855-543-3784 or 301-796-3400; Fax: 301-431-6353

druginfo@fda.hhs.gov

http://www.fda.gov/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/default.htm

or

Office of Communication, Outreach and Development

Center for Biologics Evaluation and Research

Food and Drug Administration

10903 New Hampshire Ave., Bldg. 71, Room 3128

Silver Spring, MD 20993-0002

Phone: 800-835-4709 or 240-402-8010

Email: ocod@fda.hhs.gov

https://www.fda.gov/BiologicsBloodVaccines/GuidanceComplianceRegulatoryInformation/Guidances/default.htm

U.S. Department of Health and Human Services

Food and Drug Administration

Center for Drug Evaluation and Research (CDER)

Center for Biologics Evaluation and Research (CBER)

[June 2017]

ICH

Revision 3

Contains Nonbinding Recommendations

Q3C — Tables and List

Guidance for Industry

1

This guidance represents the current thinking of the Food and Drug Administration (FDA or Agency) on

this topic. It does not establish any rights for any person and is not binding on FDA or the public. You

can use an alternative approach if it satisfies the requirements of the applicable statutes and regulations.

To discuss an alternative approach, contact the FDA office responsible for this guidance as listed on the

title page.

I. INTRODUCTION

This is the companion document for the International Council for Harmonisation of Technical

Requirements for Pharmaceuticals for Human Use (ICH) guidance for industry Q3C Impurities:

Residual Solvents, which makes recommendations as to what amounts of residual solvents are

considered safe in pharmaceuticals.

This document may be updated if proposals for change are submitted to the ICH Secretariat for

consideration by the ICH Q3C Expert Working Group (EWG). If the EWG supports the

proposal for change, the proposal will be submitted to the ICH Assembly for endorsement. Any

proposals that are endorsed by the ICH Assembly will be announced through a notice in the

Federal Register prior to the updating of this document. The guidance was revised in November

2003 to reflect updated recommendations for N-Methylpyrrolidone and Tetrahydrofuran, in

February 2012 to reflect an updated recommendation for cumene, and in October 2016 to reflect

updated recommendations for Triethylamine and Methylisobutylketone.

In general, FDA’s guidance documents do not establish legally enforceable responsibilities.

Instead, guidances describe the Agency's current thinking on a topic and should be viewed only

as recommendations, unless specific regulatory or statutory requirements are cited. The use of

the word should in Agency guidances means that something is suggested or recommended, but

not required.

1

This document was developed within the Expert Working Group (Quality) of the International Council for

Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH) and has been subject to

consultation by the regulatory parties, in accordance with the ICH process. This document was endorsed by the ICH

Steering Committee at Step 4 of the ICH process in July 1997. At Step 4 of the process, the final draft is

recommended for adoption to the regulatory agencies. This guidance was published in the Federal Register on

December 24, 1997 (62 FR 67377), and is applicable to drug and biological products.

2

The information included for Methylisobutylketone reflects that included in the Revision of PDE Information for

Methylisobutylketone, which reached Step 4 in November 2016 and was subsequently incorporated into the core

guidance.

1

Contains Nonbinding Recommendations

II. LIST OF SOLVENTS INCLUDED IN THE Q3C GUIDANCE

Solvent Other Names Structure Class

Acetic acid

Ethanoic acid

CH

3

COOH

Class 3

Acetone 2-Propanone CH

3

COCH

3

Propan-2-one

Class 3

Acetonitrile

CH

3

CN

Class 2

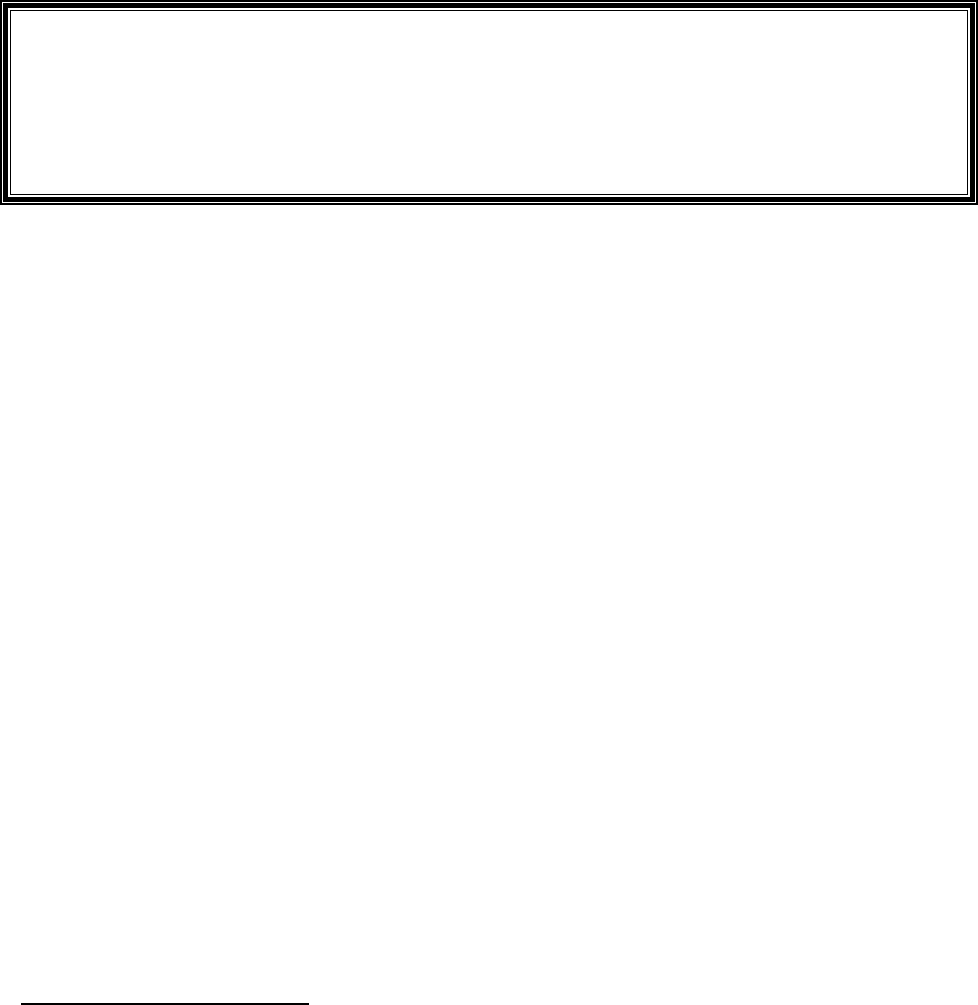

Anisole Methoxybenzene

Class 3

Benzene Benzol

Class 1

1-Butanol n-Butyl alcohol CH

3

(CH

2

)

3

OH Class 3

Butan-1-ol

2-Butanol CH

3

CH

2

CH(OH)CH

3

sec-Butyl alcohol

Class 3

Butan-2-ol

Butyl acetate

Acetic acid butyl ester

CH

3

COO(CH

2

)

3

CH

3

Class 3

tert-Butylmethyl ether

2-Methoxy-2-methyl-propane

(CH

3

)

3

COCH

3

Class 3

Carbon tetrachloride

Tetrachloromethane

CCl

4

Class 1

Chlorobenzene

Class 2

Chloroform

Trichloromethane

CHCl

3

Class 2

Cumene Isopropylbenzene

C

6

H

5

-CH(CH

3

)

2

(1-Methyl)ethylbenzene

Class 2

Cyclohexane Hexamethylene Class 2

1,2-Dichloroethane CH

2

ClCH

2

Cl

sym-Dichloroethane

Class 1

Ethylene dichloride

Ethylene chloride

1,1-Dichloroethene 1,1-Dichloroethylene H

2

C=CCl

2

Vinylidene chloride

Class 1

1,2-Dichloroethene 1,2-Dichloroethylene ClHC=CHCl

Acetylene dichloride

Class 2

2

Contains Nonbinding Recommendations

Dichloromethane

Methylene chloride

CH

2

Cl

2

Class 2

1,2-Dimethoxyethane

Ethyleneglycol dimethyl ether

Monoglyme

Dimethyl Cellosolve

H

3

COCH

2

CH

2

OCH

3

Class 2

N,N-

Dimethylacetamide

DMA

CH

3

CON(CH

3

)

2

Class 2

N,N- Dimethylformamide

DMF

HCON(CH

3

)

2

Class 2

Dimethyl sulfoxide

Methylsulfinylmethane

Methyl sulfoxide

DMSO

(CH

3

)

2

SO

Class 3

1,4-Dioxane

p-Dioxane

[1,4]Dioxane

Class 2

Ethanol

Ethyl alcohol

CH

3

CH

2

OH

Class 3

2-Ethoxyethanol

Cellosolve

CH

3

CH

2

OCH

2

CH

2

OH

Class 2

Ethyl acetate

Acetic acid ethyl ester

CH

3

COOCH

2

CH

3

Class 3

Ethyleneglycol

1,2-Dihydroxyethane

1,2-Ethanediol

HOCH

2

CH

2

OH

Class 2

Ethyl ether

Diethyl ether

Ethoxyethane

1,1’-Oxybisethane

CH

3

CH

2

OCH

2

CH

3

Class 3

Ethyl formate

Formic acid ethyl ester

HCOOCH

2

CH

3

Class 3

Formamide

Methanamide

HCONH

2

Class 2

Formic acid

HCOOH

Class 3

Heptane

n-Heptane

CH

3

(CH

2

)

5

CH

3

Class 3

Hexane

n-Hexane

CH

3

(CH

2

)

4

CH

3

Class 2

Is obutyl acetate

Acetic acid isobutyl ester

CH

3

COOCH

2

CH(CH

3

)

2

Class 3

Isopropyl acetate

Acetic acid isopropyl ester

CH

3

COOCH(CH

3

)

2

Class 3

Methanol

Methyl alcohol

CH

3

OH

Class 2

2-Methoxyethanol

Methyl Cellos olve

CH

3

OCH

2

CH

2

OH

Class 2

Methyl acetate

Acetic acid methyl ester

CH

3

COOCH

3

Class 3

3-Methyl-1-butanol

Isoamyl alcohol

Isopentyl alcohol

3-Methylbutan-1-ol

(CH

3

)

2

CHCH

2

CH

2

OH

Class 3

3

Contains Nonbinding Recommendations

Methylbutyl ketone

2-Hexanone

Hexan-2-one

CH

3

(CH

2

)

3

COCH

3

Class 2

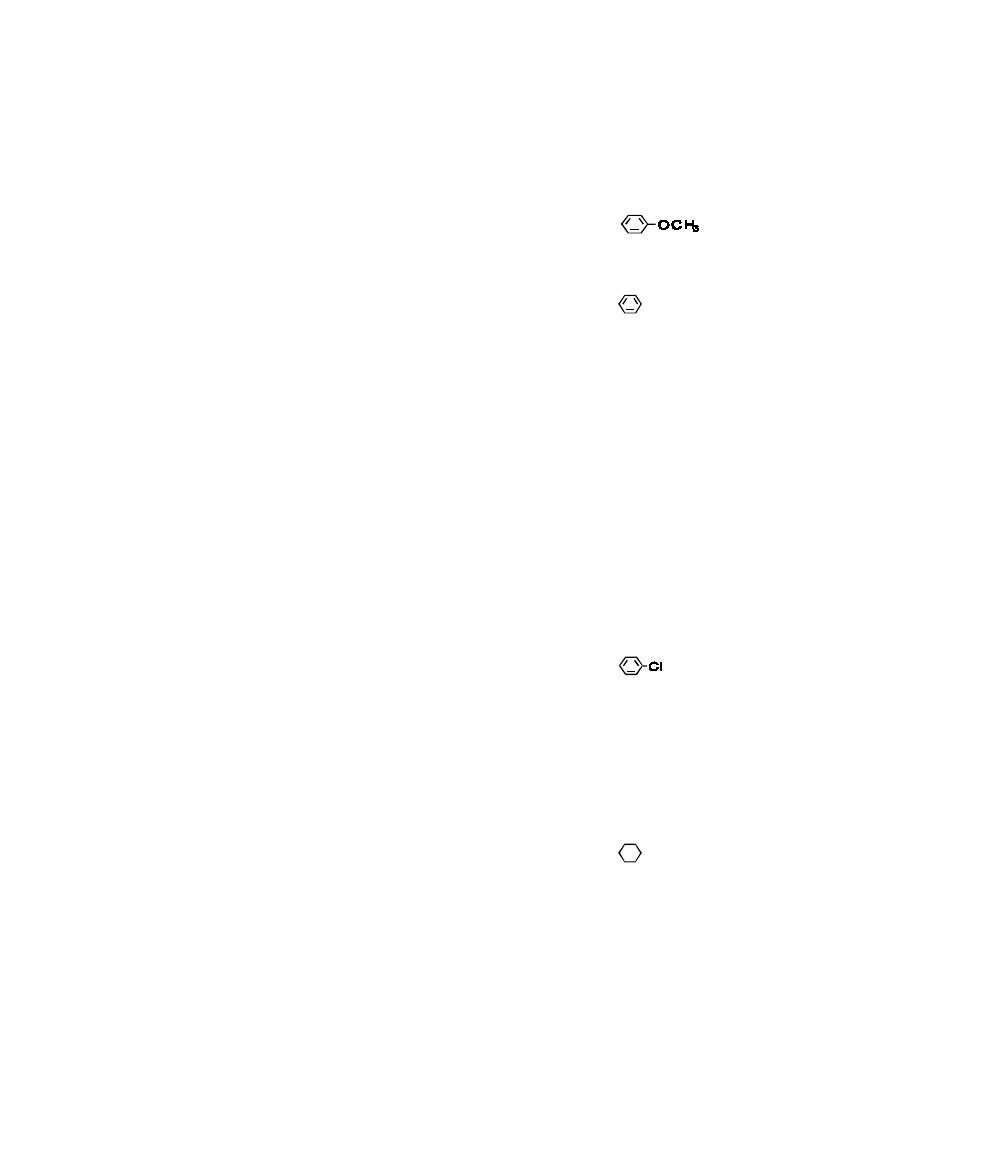

Methylcyclohexane

Cyclohexylmethane

Class 2

Methylethyl ketone

2-Butanone

MEK

Butan-2-one

CH

3

CH

2

COCH

3

Class 3

Methylisobutyl ketone

4-Methylpentan-2-one

4-Methyl-2-pentanone

MIBK

CH

3

COCH

2

CH(CH

3

)

2

Class 2

2-Methyl-1-propanol

Isobutyl alcohol

2-Methylpropan-1-ol

(CH

3

)

2

CHCH

2

OH

Class 3

N-Methylpyrrolidone

1-Methylpyrrolidin-2-one

1-Methyl-2-pyrrolidinone

Class 2

Nitromethane

CH

3

NO

2

Class 2

Pentane

n-Pentane

CH

3

(CH

2

)

3

CH

3

Class 3

1-Pentanol

Amyl alcohol

Pentan-1-ol

Pentyl alcohol

CH

3

(CH

2

)

3

CH

2

OH

Class 3

1-Propanol

Propan-1-ol

Propyl alcohol

CH

3

CH

2

CH

2

OH

Class 3

2-Propanol

Propan-2-ol

Isopropyl alcohol

(CH

3

)

2

CHOH

Class 3

Propyl acetate

Acetic acid propyl ester

CH

3

COOCH

2

CH

2

CH

3

Class 3

Pyridine

Class 2

Sulfolane

Tetrahydrothiophene 1,1-dioxide

Class 2

Tetrahydrofuran

Tetramethylene oxide

Oxacyclopentane

Class 2

Tetralin

1,2,3,4-Tetrahydro-naphthalene

Class 2

Toluene

Methylbenzene

Class 2

1,1,1-Trichloroethane

Methylchloroform

CH

3

CCl

3

Class 1

1,1,2-Trichloroethene

Trichloroethene

HClC=CCl

2

Class 2

Triethylamine

N,N-Diethylethanamine

N(CH

2

CH

3

)

3

Class 3

4

Contains Nonbinding Recommendations

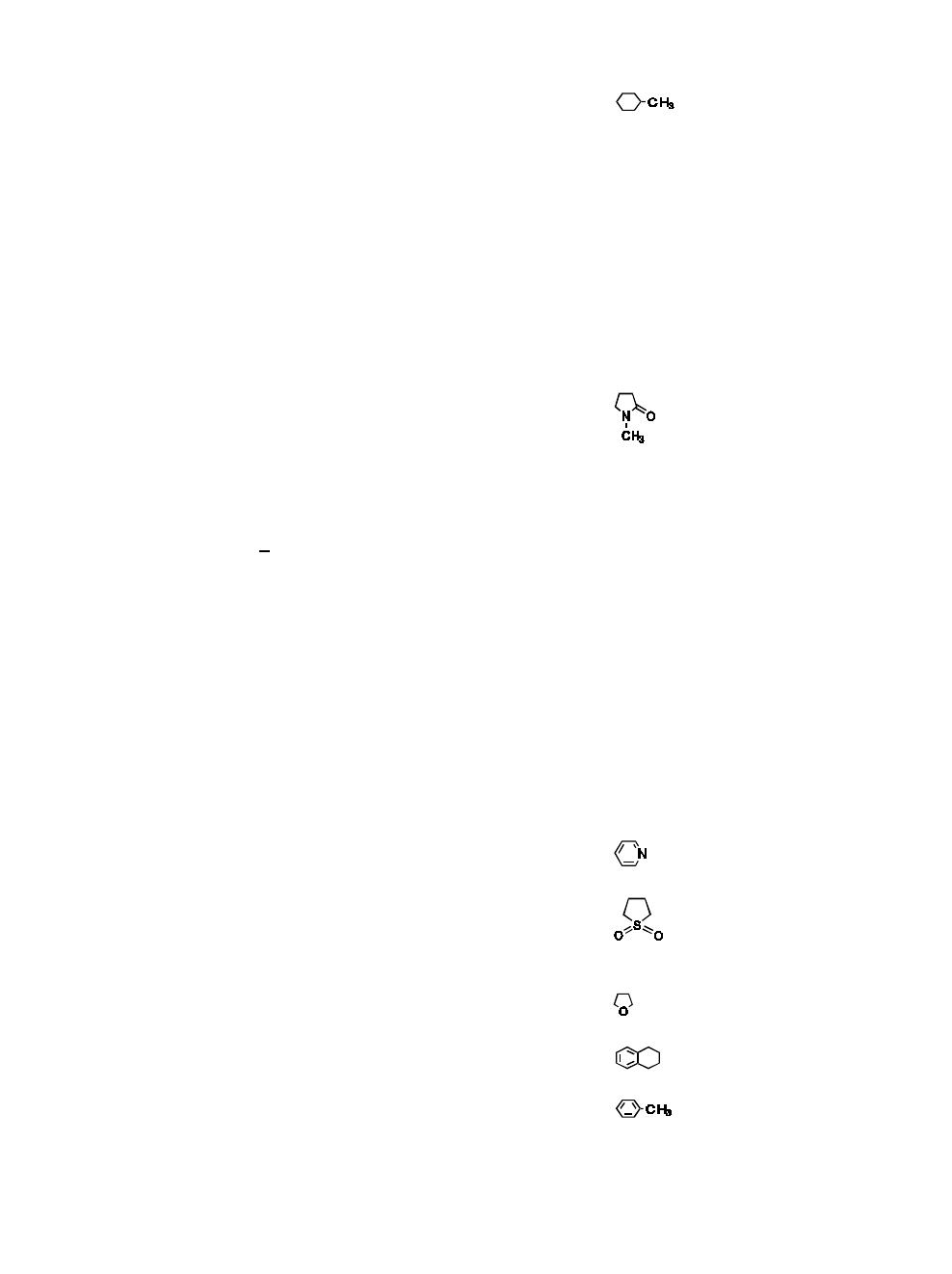

Xylene

1

Dimethybenzene

Xylol

Class 2

1

Us ually 60% m-xylene, 14% p-xylene, 9% o-xylene with 17% ethyl benzene.

III. SOLVENTS GROUPED BY CLASS

Solvents in Class 1 (Table 1) should not be employed in the manufacture of drug substances,

excipients, and drug products because of their unacceptable toxicity or their deleterious

environmental effect. However, if their use is unavoidable in order to produce a drug product

with a significant therapeutic advance, then their levels should be restricted as shown in Table 1,

unless otherwise justified. The solvent 1,1,1-Trichloroethane is included in Table 1 because it is

an environmental hazard. The stated limit of 1,500 ppm is based on a review of the safety data.

Table 1. – Class 1 Solvents in Pharmaceutical Products (Solvents That Should Be Avoided)

Solvent

Concentration Limit

(ppm)

Concern

Benzene

Carbon tetrachloride

2

4

Carcinogen

Toxic and environmental hazard

1,2-Dichloroethane

5

Toxic

1,1-Dichloroethene

8

Toxic

1,1,1-Trichloroethane 1,500 Environmental hazard

5

Contains Nonbinding Recommendations

Solvents in Class 2 (Table 2) should be limited in pharmaceutical products because of their

inherent toxicity. PDEs are given to the nearest 0.1 mg/day, and concentrations are given to the

nearest 10 ppm. The stated values do not reflect the necessary analytical precision of

determination. Precision should be determined as part of the validation of the method.

Table 2. – Class 2 Solvents in Pharmaceutical Products

Solvent

PDE (mg/day)

Concentration Limit (ppm)

Acetonitrile

4.1

410

Chlorobenzene

3.6

360

Chloroform

0.6

60

Cyclohexane

38.8

3,880

Cumene

0.7

70

1,2-Dichloroethene

18.7

1,870

Dichloromethane

6.0

600

1,2-Dimethoxyethane

1.0

100

N,N-Dimethylacetamide

10.9

1,090

N,N-Dimethylformamide

8.8

880

1,4-Dioxane

3.8

380

2-Ethoxyethanol

1.6

160

Ethyleneglycol

6.2

620

Formamide

2.2

220

Hexane

2.9

290

Methanol

30.0

3,000

2-Methoxyethanol

0.5

50

Methylbutyl ketone

0.5

50

Methylcyclohexane

11.8

1,180

Methylisobutylketone

2

45

4,500

N-Methylpyrrolidone

5.3

530

Nitromethane

0.5

50

Pyridine

2.0

200

Sulfolane

1.6

160

Tetrahydrofuran

7.2

720

Tetralin

1.0

100

2

The information included for Methylisobutylketone reflects that included in the Revision of PDE Information for

Methylisobutylketone, which reached Step 4 in November 2016 and was subsequently incorporated into the core

guidance.

6

Contains Nonbinding Recommendations

Toluene

8.9

890

1,1,2-Trichloroethene

0.8

80

Xylene

1

21.7

2,170

1

Us ually 60% m-xylene, 14% p-xylene, 9% o-xylene with 17% ethyl benzene.

Solvents in Class 3 (Table 3) may be regarded as less toxic and of lower risk to human health.

Class 3 includes no solvent known as a human health hazard at levels normally accepted in

pharmaceuticals. However, there are no long-term toxicity or carcinogenicity studies for many

of the solvents in Class 3. Available data indicate that they are less toxic in acute or short-term

studies and negative in genotoxicity studies. It is considered that amounts of these residual

solvents of 50 mg per day or less (corresponding to 5,000 ppm or 0.5 percent under Option 1)

would be acceptable without justification. Higher amounts may also be acceptable provided they

are realistic in relation to manufacturing capability and good manufacturing practice (GMP).

Table 3. – Class 3 Solvents Which Should Be Limited by GMP or Other Quality-Based

Requirements

Acetic acid

Heptane

Acetone Is obutyl acetate

Anisole Isopropyl acetate

1-Butanol Methyl acetate

2-Butanol 3-Methyl-1-butanol

Butyl acetate Methylethyl ketone

tert-Butylmethyl ether 2-Methyl-1-propanol

Dimethyl sulfoxide Pentane

Ethanol 1-Pentanol

Ethyl acetate 1-Propanol

Ethyl ether 2-Propanol

Ethyl formate Propyl acetate

Formic acid

Triethylamine

3

3

The information included for Triethylamine reflects that included in the Revision of PDE Information for

Triethylamine, which reached Step 4 in November 2016 and was subsequently incorporated into the core guidance.

7

Contains Nonbinding Recommendations

The solvents listed in Table 4 may also be of interest to manufacturers of excipients, drug

substances, or drug products. However, no adequate toxicological data on which to base a PDE

were found. Manufacturers should supply justification for residual levels of these solvents in

pharmaceutical products.

Table 4. – Solvents for Which No Adequate Toxicological Data Were Found

1,1-Diethoxypropane

Methylisopropyl ketone

1,1-Dimethoxymethane Methyltetrahydrofuran

2,2-Dimethoxypropane

Petroleum ether

Isooctane

Trichloroacetic acid

Isopropyl ether

Trifluoroacetic acid

8